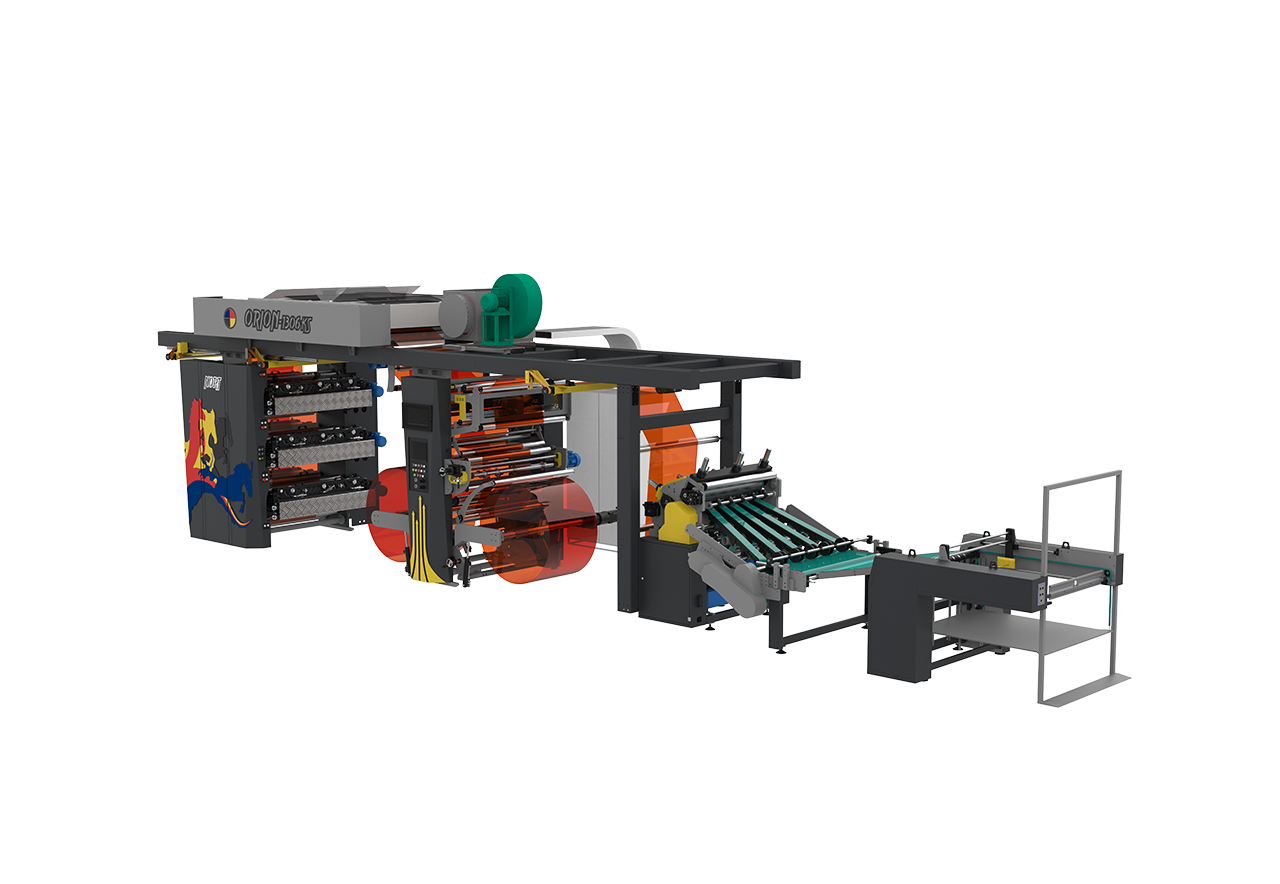

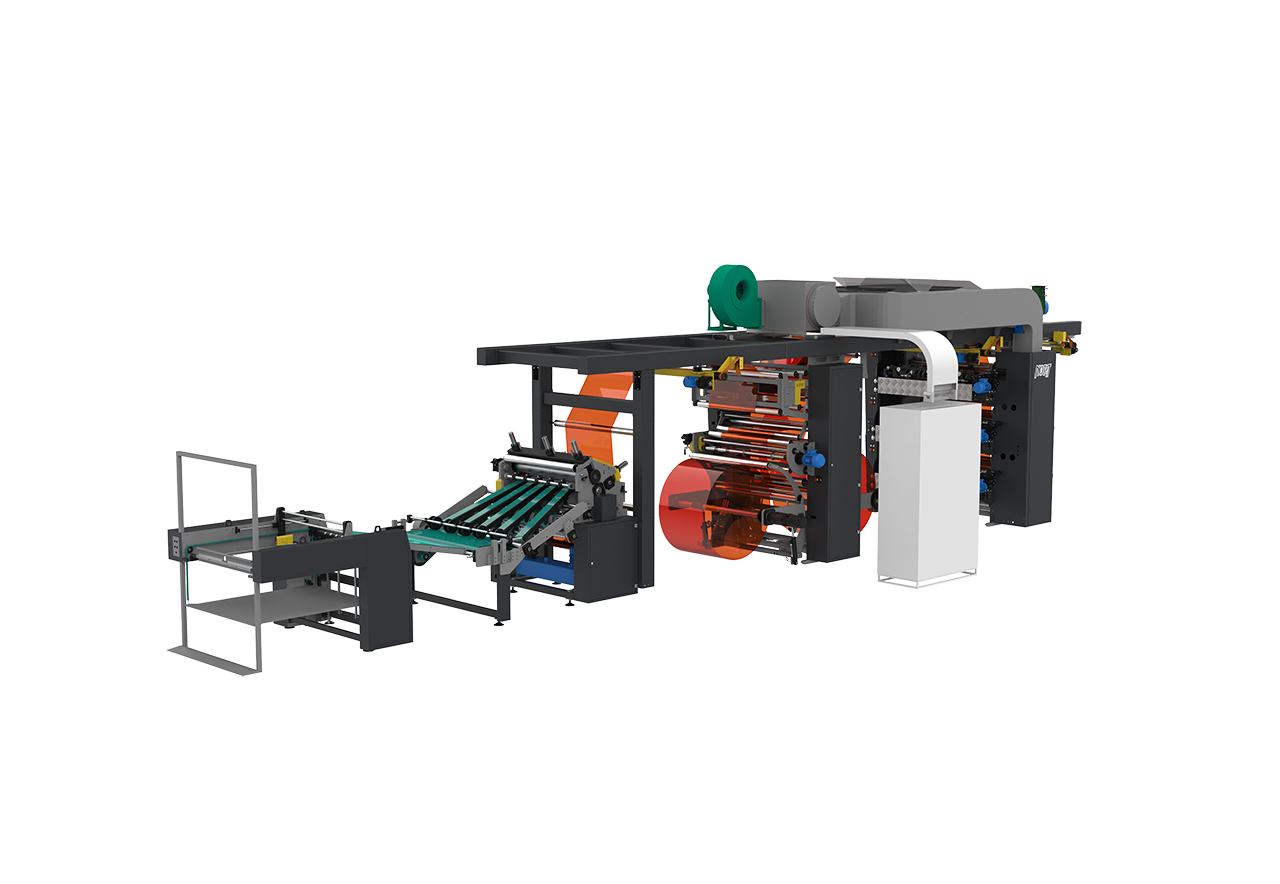

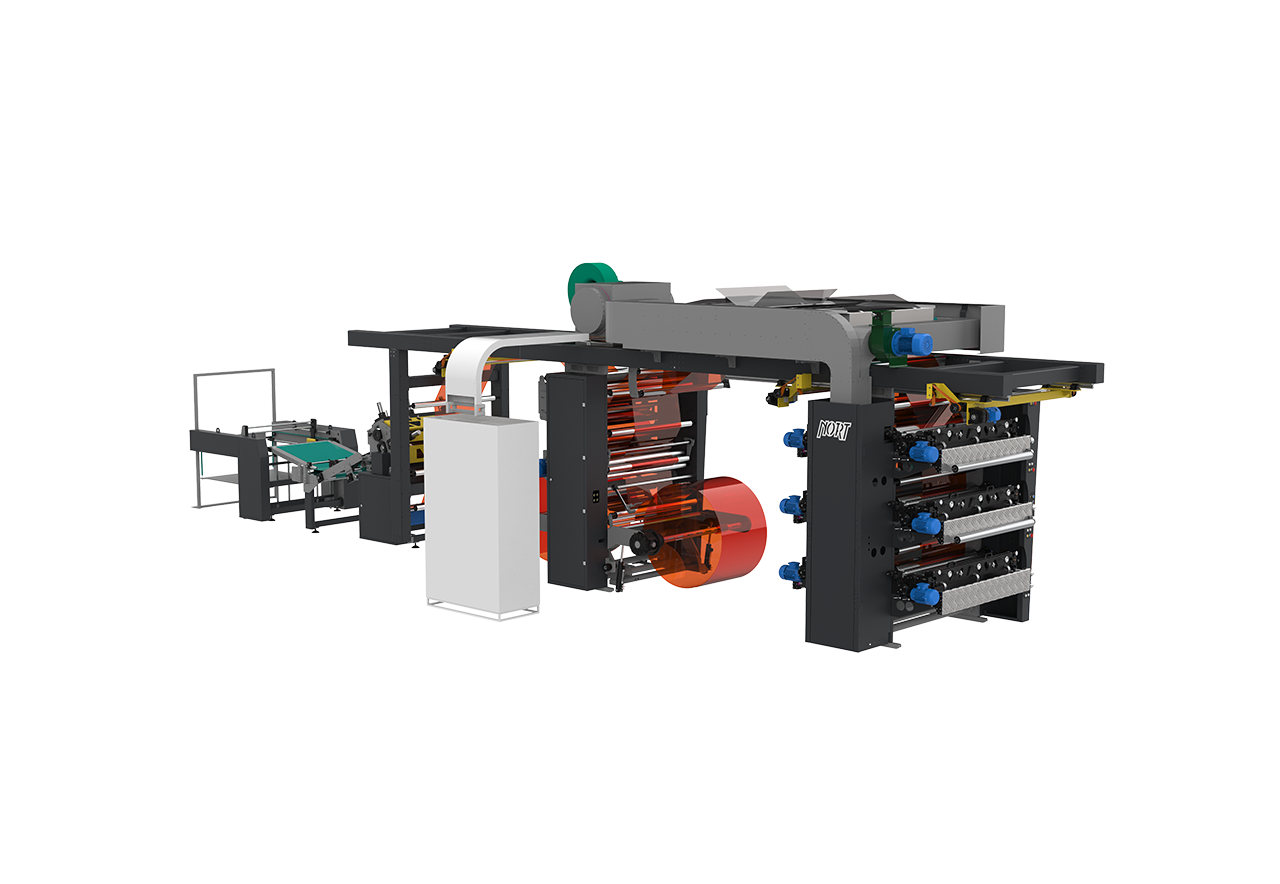

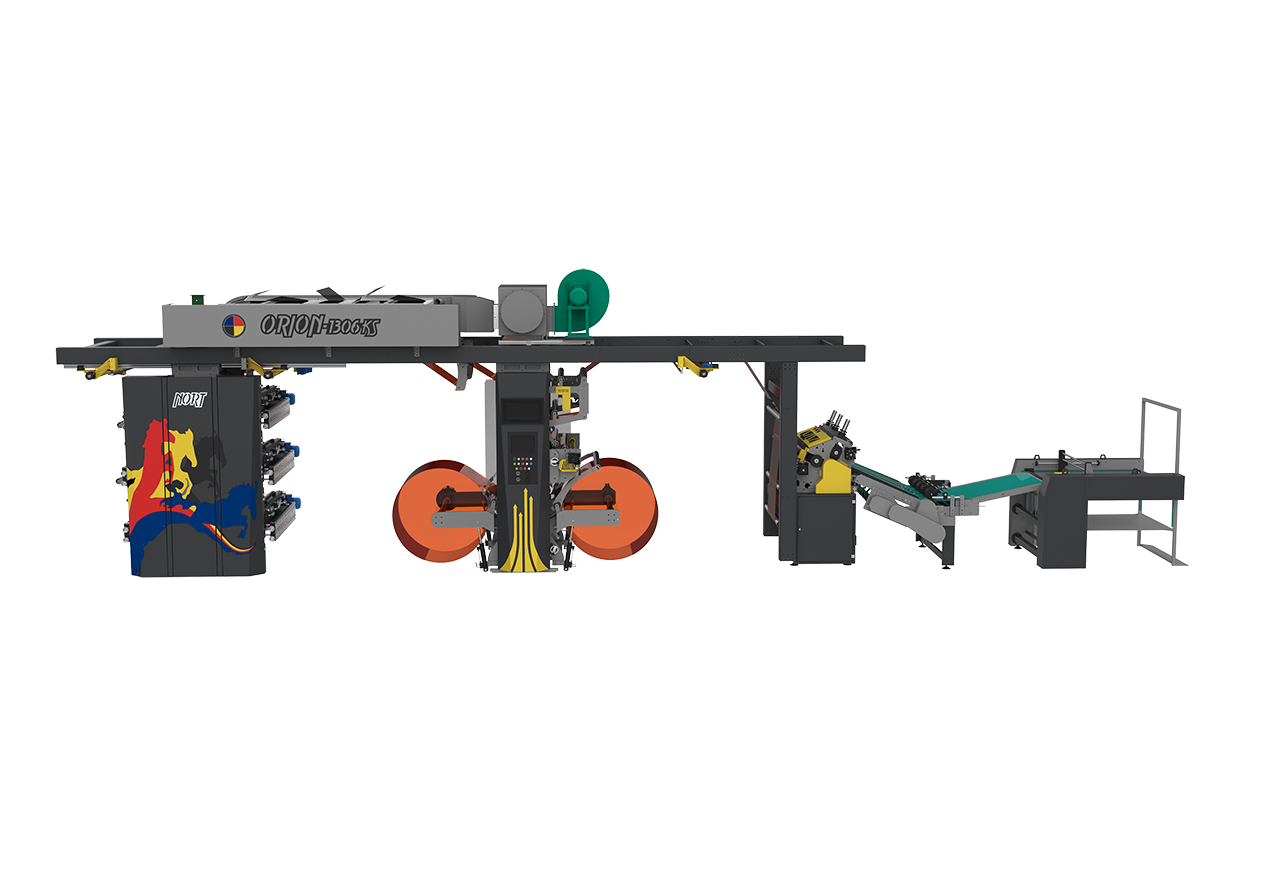

PRINTING FEATURES

WRAPPER MAX : Ø 1200 mm

SOLVENT MAX : Ø 1200mm

WORKABLE PRODUCT WIDTH : 1350 mm

WORKABLE PRINTING WIDTH : 1300 mm

UNCOVERING BOBBIN DIAMETER : Ø 76 mm (3”) steel Airshaft

WINDER BOBBIN DIAMETER : Ø 76 mm (3”) steel Airshaft

PRINTING UNIT : 6 Colors

SOLVENT TENSION : Min 25 – Max 400 Nm

PRINTING ABILITY : 6+0

PRINT REPEAT : 250 – 750 mm

GEAR PITCH : 5 mm

PLATE THICKNESS : 1.14 mm

MACHINE MECHANICAL SPEED : 200 m/ min

PRINTING SPEED : 200 m/ min

WINDING GROUP1 Winding Unit (Main Body Coupled )

The intermediate tractor is a SERVO motor

Transducer ruler ballerina blood pressure control

Max Winder Diameter 1200 mm

Hydraulic loading and unloading

Manual edge control

SOLVENTOR GROUP

1 Solver Unit (Main Body Coupled )

Transducer ruler ballerina and proportional controlled air brake

Automatic edge control ( ultrasonic control)

Max Solver Diameter 1200 mm

Hydraulic loading and unloading

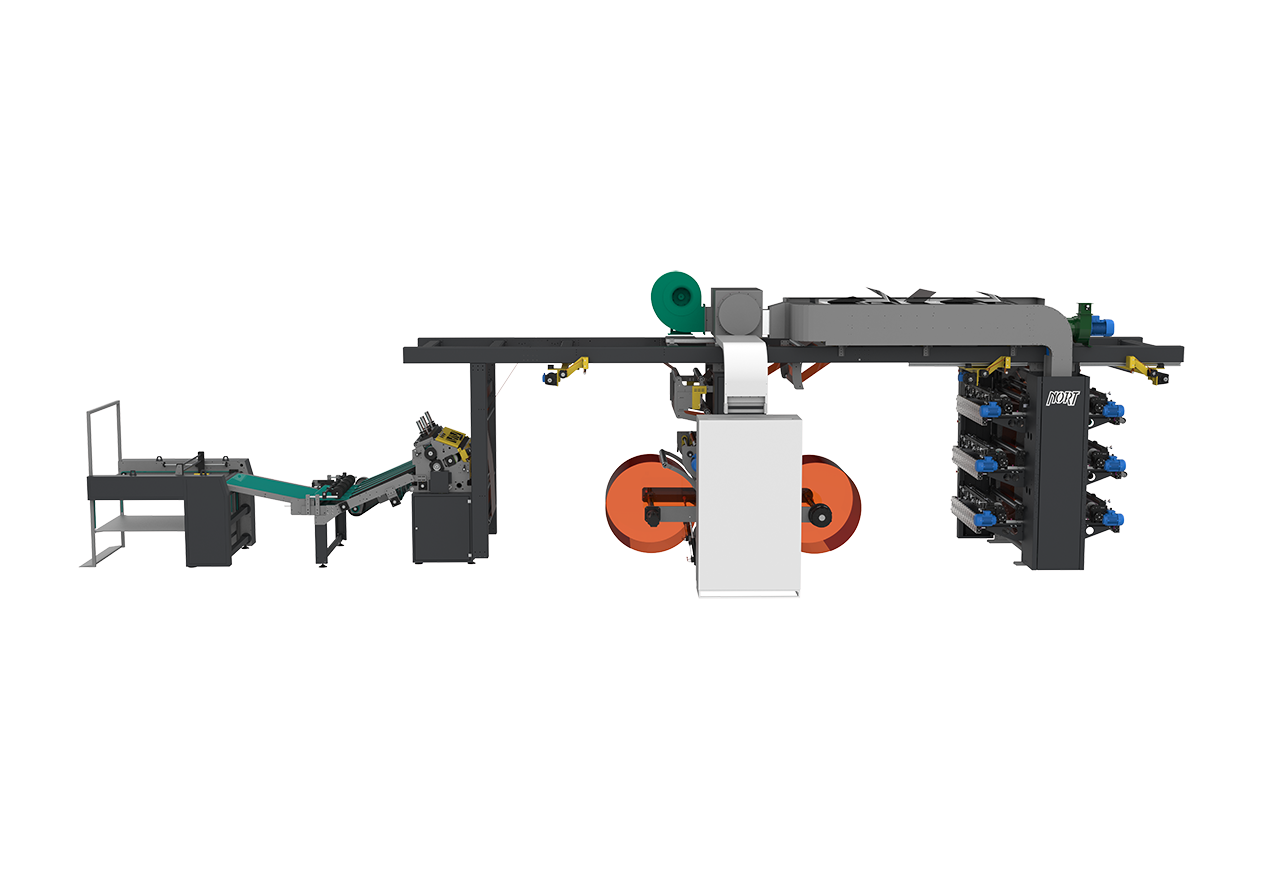

ROTARY KNIFE

· PRODUCT CUTTING SYSTEM : DOUBLE BLADE ROTARY CUT

· PRODUCT PAPER WIDTH: 1050 MM

· PRODUCT PAPER SPEED: 120 Mt / min

· CUTTING TO LENGTH : MAGNETIC BLADE ON MAGNETIC TANBUR

· CUTTING TO LENGTH : 518-628 MM (suitable for all glasses)

· HEIGHT ADJUSTMENT: SERVO CONTROL

· PRODUCT PULLING SYSTEM : SERVO MOTOR

· BLADE PRESSURE SYSTEM : HYDRAULIC CONTROL

MACHINE WORKING SYSTEM ( The machine is used in two ways.)

1- PRINTING GROUP: If this working method is selected in the machine ; 6 color closed squeegees are used for the bobbins in the 1300mm wide unwinding groups. stack It prints with a flexo system at a speed of 200 mt / min and wraps the winder section in the rear group and prints from reel to reel. Closed squeegee dye groups are supported by 6 pump systems. The printing house visual camera system is supported and the printing web makes +/-10mm manual adjustment. Servo controlled 360 degree adjustment can be made in length printing adjustment. There are intermediate dryers in the printing groups and the main drying cabin at the upper exit of the machine provides finish drying in the printing. Printing is supported by 2 sliding cranes. The coil loading groups provide hydraulic manual loading and unloading.

ROTARY DIE CUT GROUP: If this working type is selected in the machine; 1100mm wide unwinder 6 color closed squeegee for bobbins in groups stack By pressing at a speed of 120 meters / min with the flexo system , bypassing the winding section in the rear group, rotary from the upper product path behind the machine die It comes to the cut unit. Here, the paper is aligned with automatic web control and enters the double knife unit. (This unit consists of double magnetic drums. And it works by connecting a blanket knife to it. The length cutting pattern adjustment of the blades is aligned with the servo . The pattern insertion of the blades into each other is provided mechanically. In the change of pattern, the magnetic drums are changed with the help of the sliding crane on the upper part.) The paper coming out of the knife drums is separated by the adjustable 5-way vacuum spacer conveyor and transferred to the herringbone arrangement conveyor behind it. (The remaining cut edges (waste) from the cut are dropped under the conveyor.) The aligned cuts here are arranged on the rear collection elevator with the help of adjustable guides. There is a side slapping system here that ventilates the product during arrangement. When the arrangement number is completed, the comb system under the herringbone conveyor moves forward and takes over the arrangement process. In the meantime, the bale arranged on the elevator goes down and leaves the bale to the waiting conveyor. And it goes up and takes over the arrangement on the comb. The comb that is used up returns to the station under the conveyor. In this way, the press and the machine work non- stop . Each time the elevator goes down, the waiting conveyor slides one product length and the product backs up