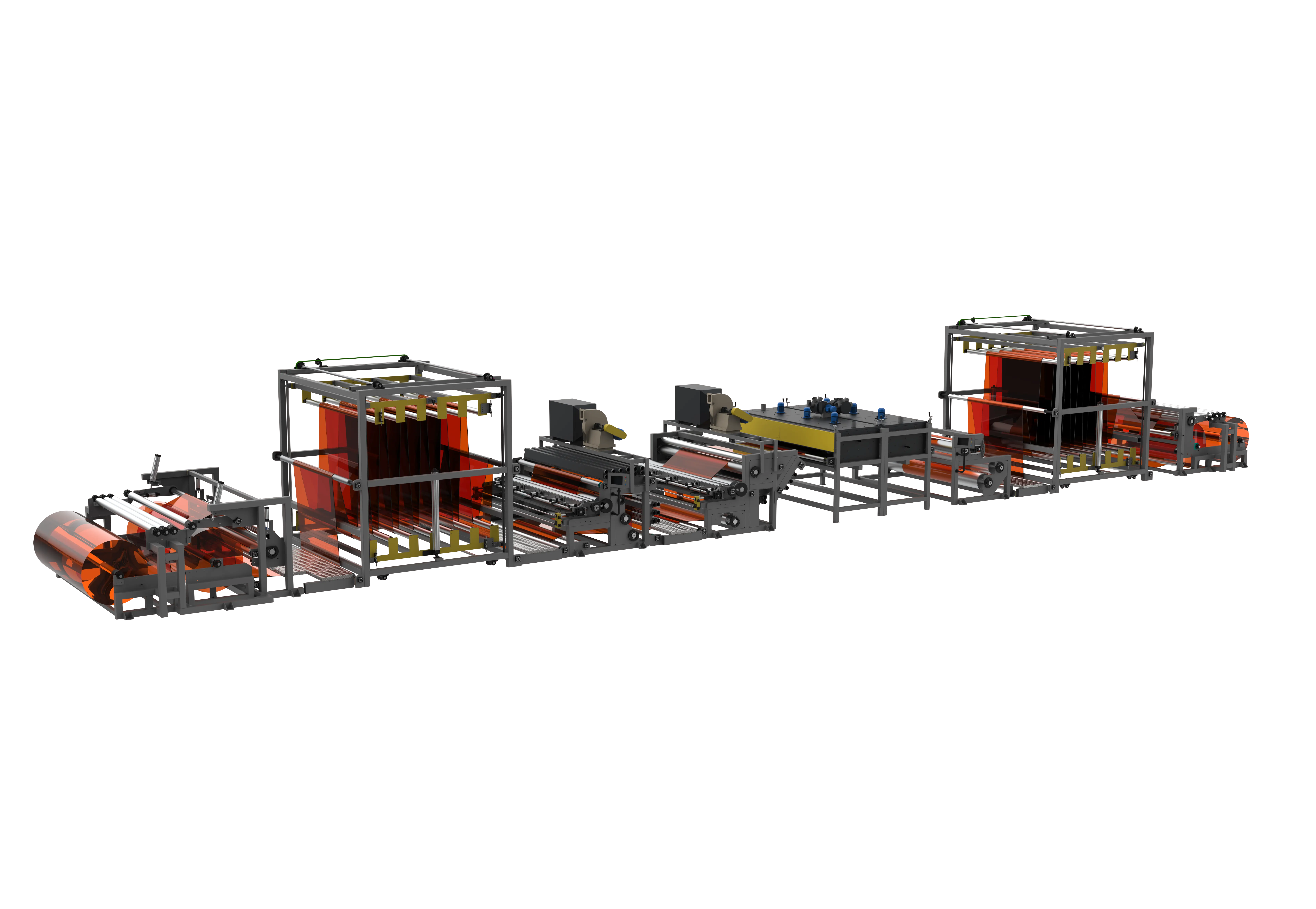

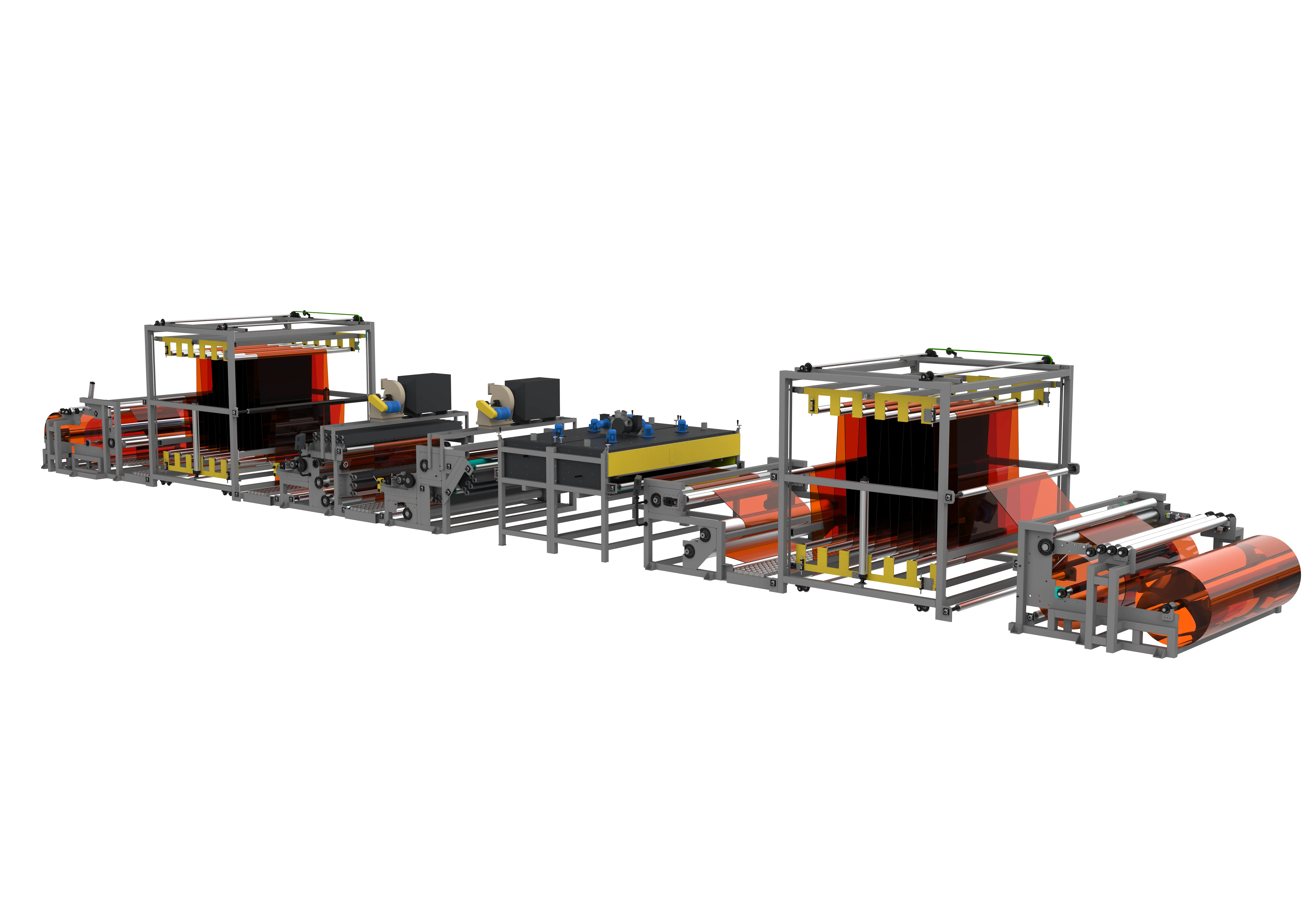

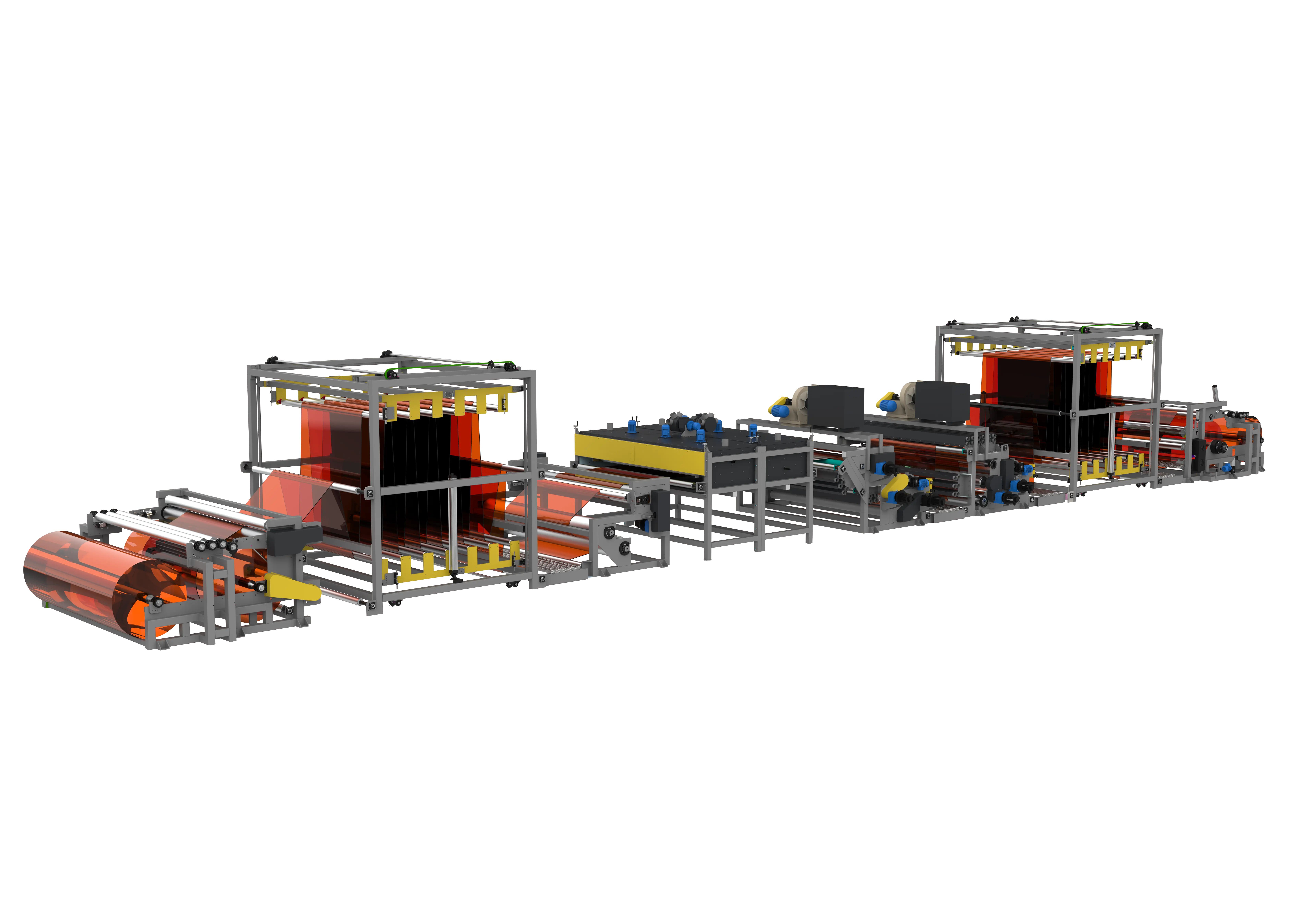

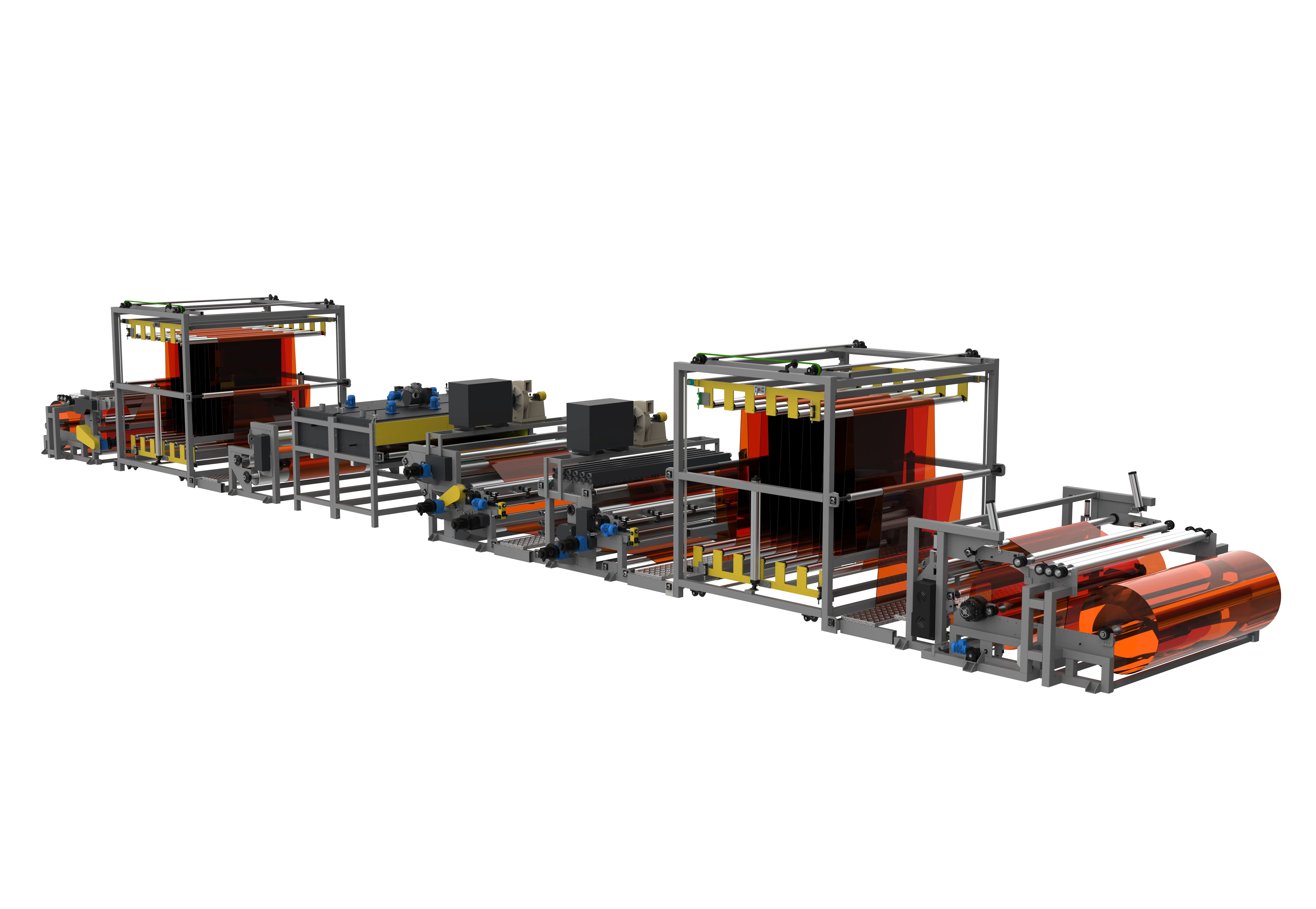

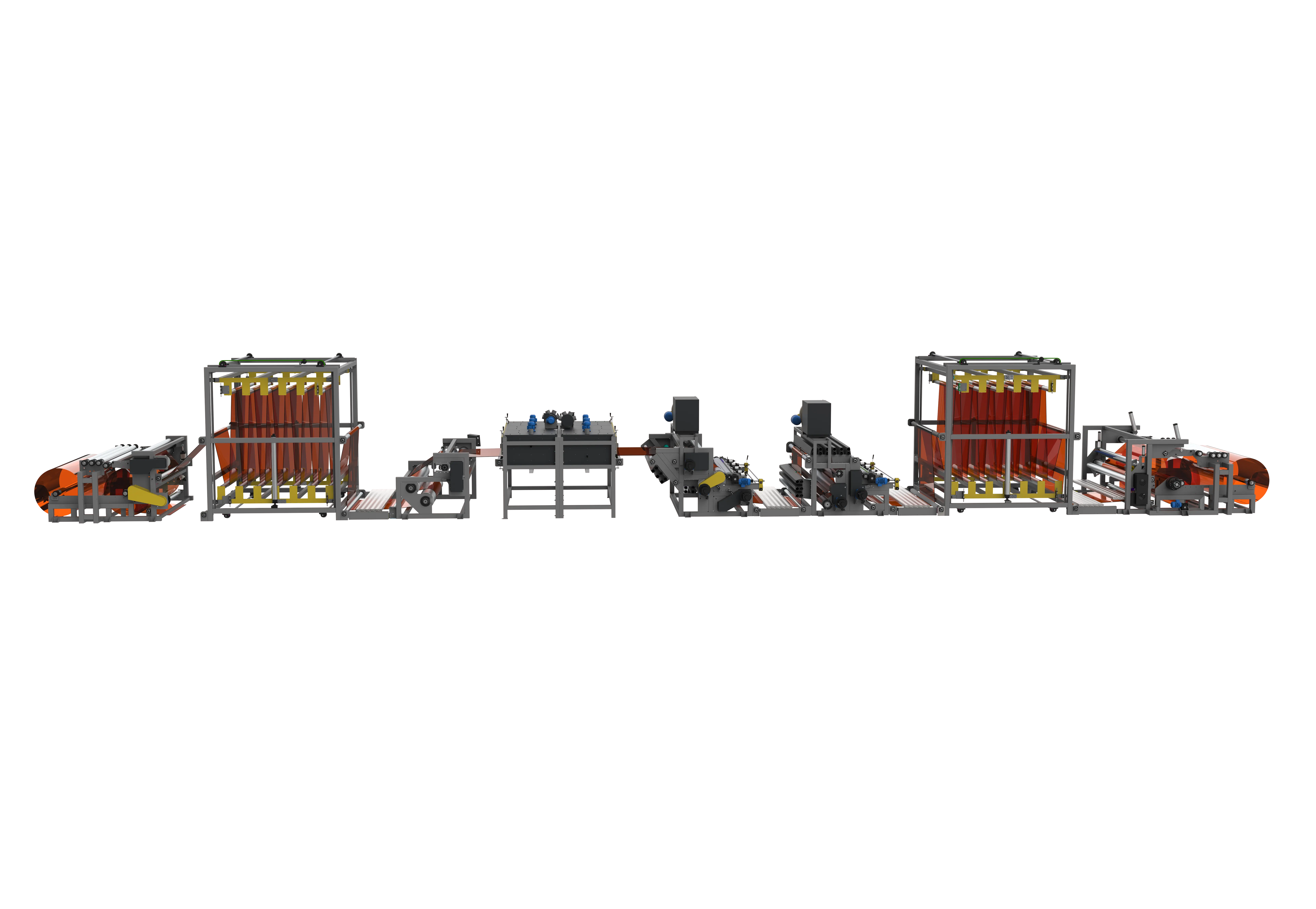

TECHNICAL SPECIFICATIONS

WORKABLE PRODUCT WIDTH : 3400 mm

WORKABLE PRINTING WIDTH : 3350 mm

PRINTING UNIT : 2 Colors

PRINTING ABILITY : 2+0/1+1

PRINT REPEAT : 300-800 mm

GEAR PITCH : 10 mm

PLATE THICKNESS : 2.54 mm

MACHINE MECHANICAL SPEED : 30 mt/min

PRINTING SPEED : 20m/min

PRINTING TYPE : closed squeegee

MIXER MOTOR : ASYNCHRONOUS MOTOR 2 PCS

TRAM ROLLER : 30 steel tram

SYSTEM : SERVO MOTOR TRACKING

CHURCH BOILER : 2 PIECES ………. LUK ROLLING PIN

PAINT FEEDING : RUST PAN / FEEDING AND MIXING WITH PUMP

THE WORKING SPEED OF THE MACHINE VARIES DEPENDING ON THE PRODUCT AND ITS STRUCTURE.

WRAPPER GROUP

1 Winding Unit (Main Body Coupled)

Transducer ruler ballerina blood pressure control

Max Winder Diameter 1200 mm

Hydraulic loading and unloading

Second product preparation available

Automatic edge control

Non-stop battery feeding

SOLVENTOR GROUP

1 Solvent Unit (Main Body Coupled)

Transducer scale ballerina (SICK ) and proportional controlled air brake (RE Italy)

Automatic edge control (ultrasonic control)

Max Solver Diameter 1200 mm

Hydraulic loading and unloading

Product weight max 3500 kg

Second product preparation system with hydraulic arm available

Non-stop battery feeding

TUNNEL

Two types of tunnels will be used in the system. The steam supply for the nozzle system as an intermediate dryer will be provided by the company. The steam air conditioning and suction-pressure system.

COOLING SYSTEM

The air conditioning system will be made with water circulation using 2 chrome rollers.