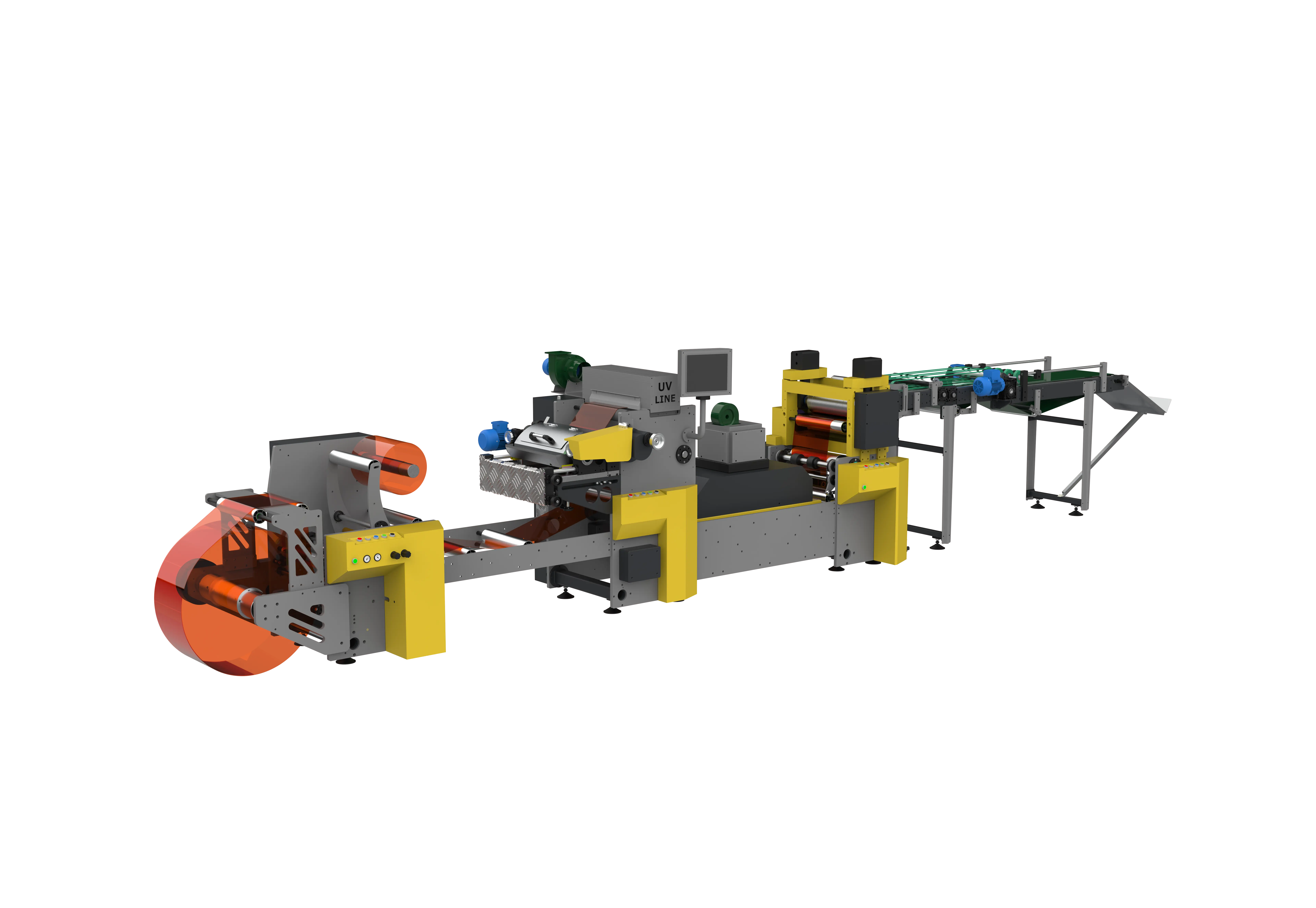

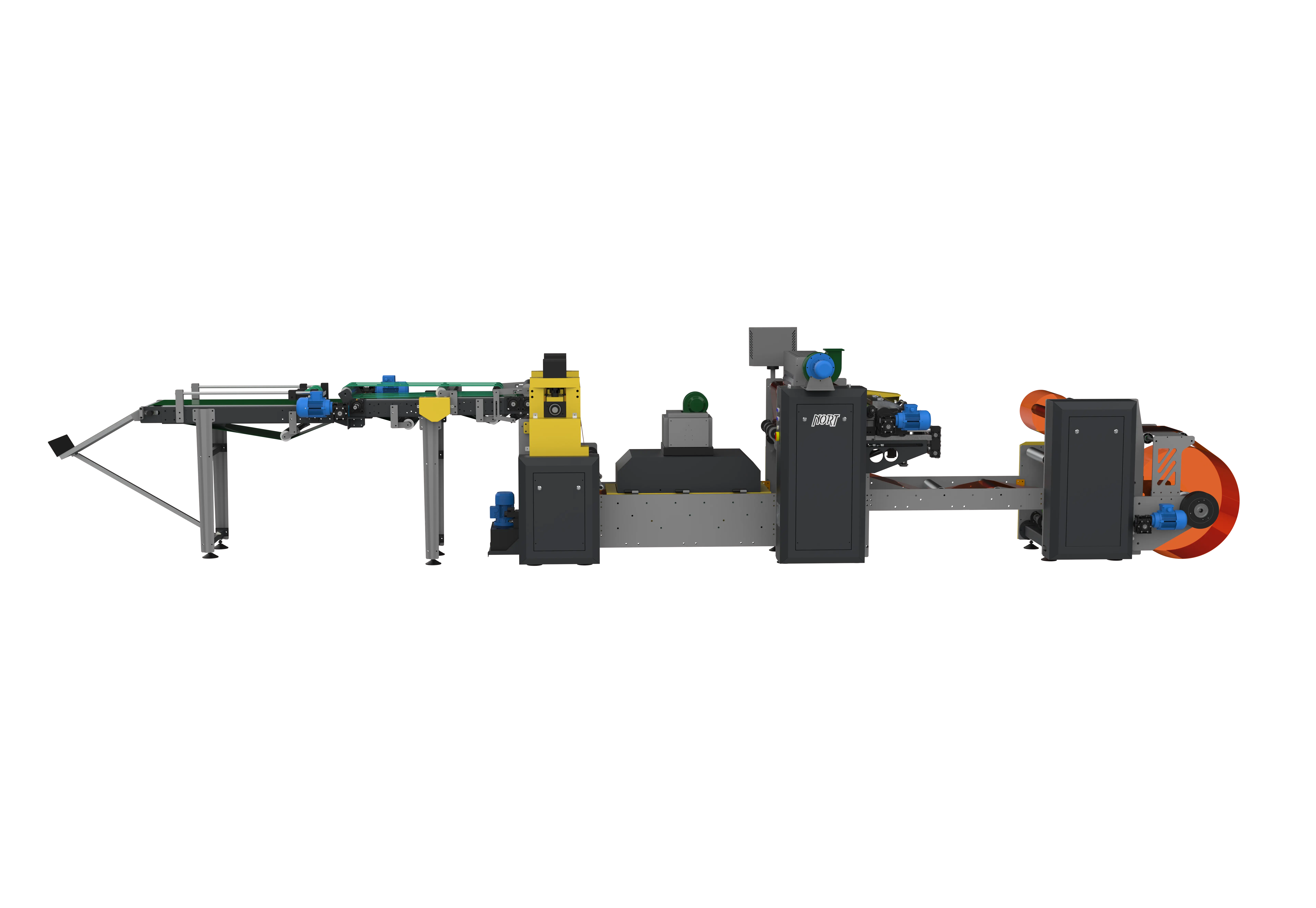

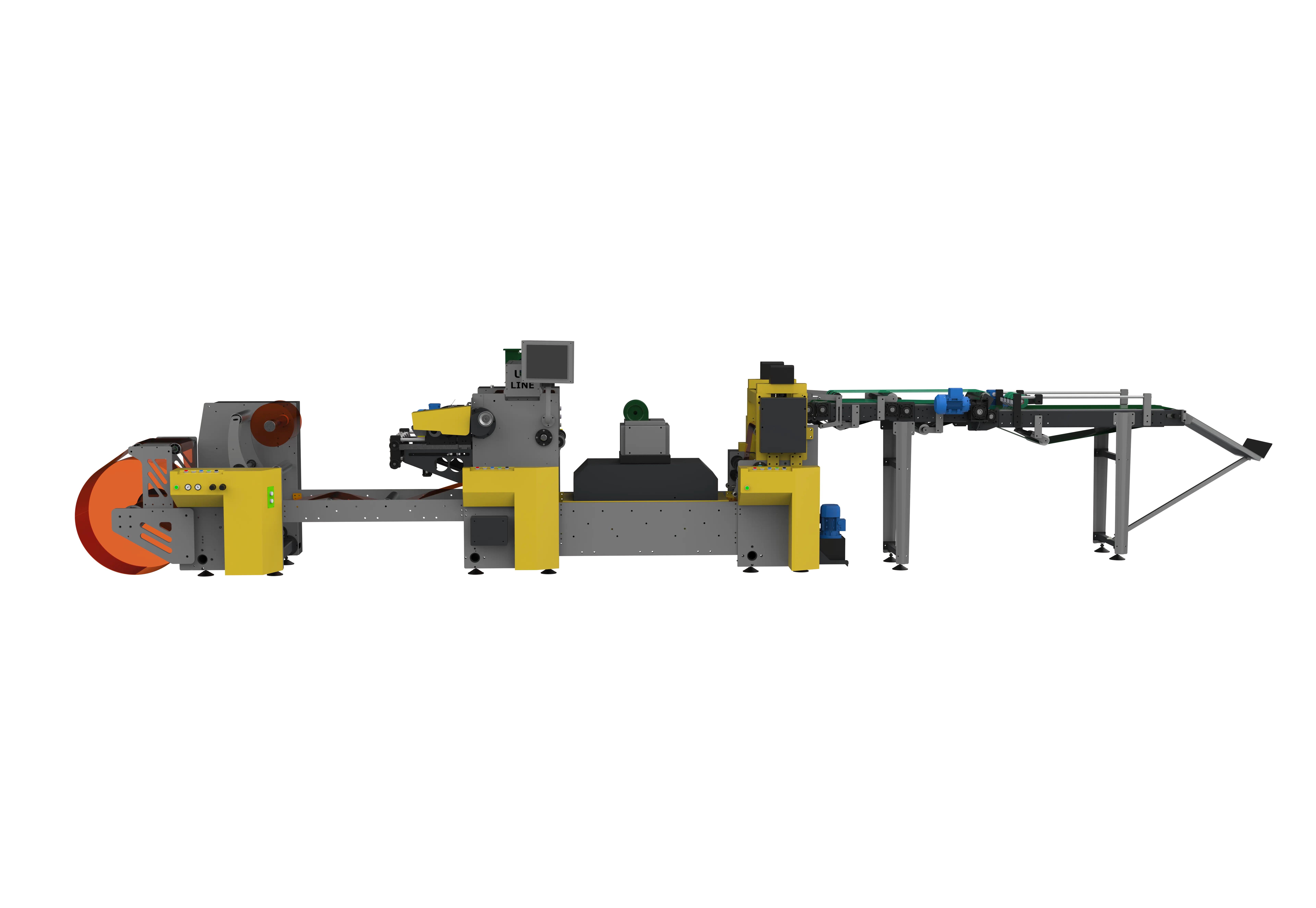

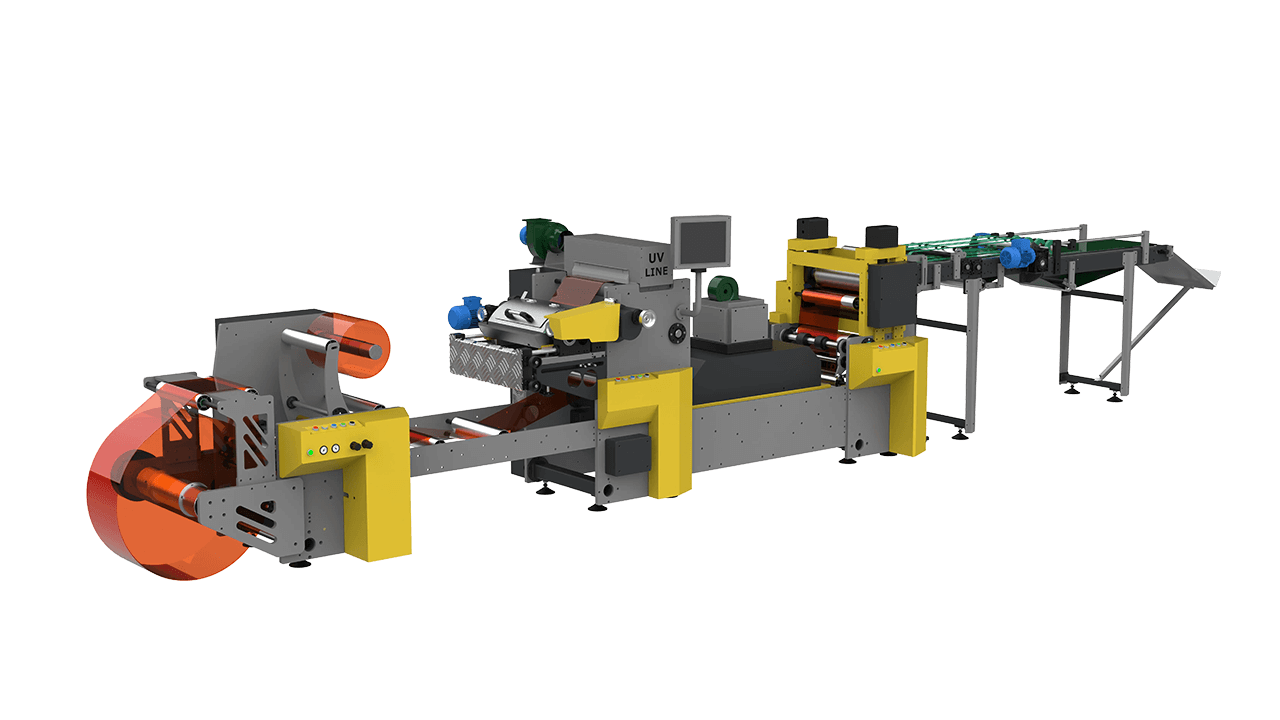

UNCOUNTER GROUP

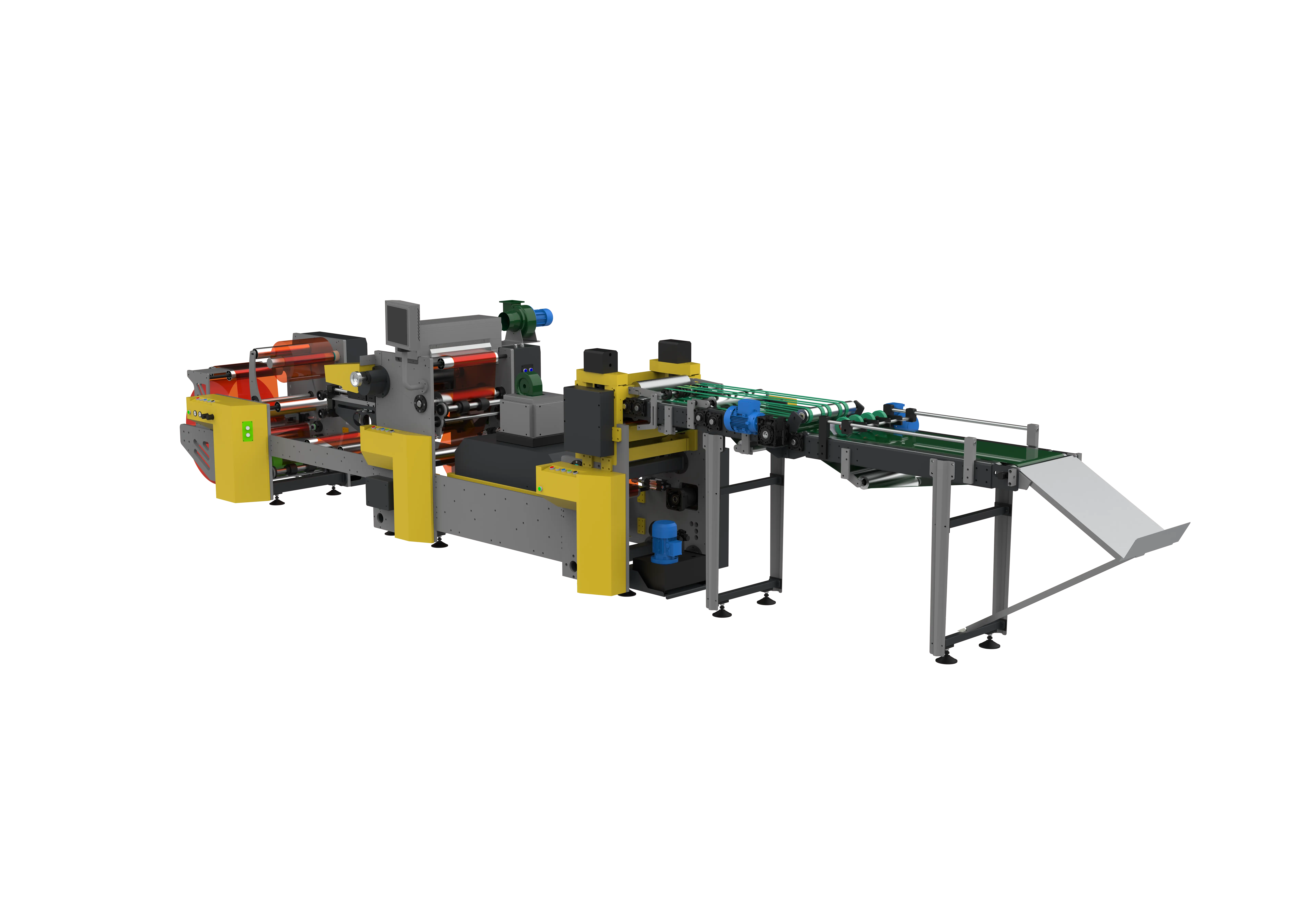

· 1 Unit Uncoiler Unit (External Body)

· Magnetic brake / Loadcell system

· Automatic edge control (fork sensor)

· Max Uncoiler Diameter 800 mm

· Foil annealing roller (heat controlled system)

· Stretch wrapping system (foil peeling / asynchronous motor with driver)

· Product adding stand

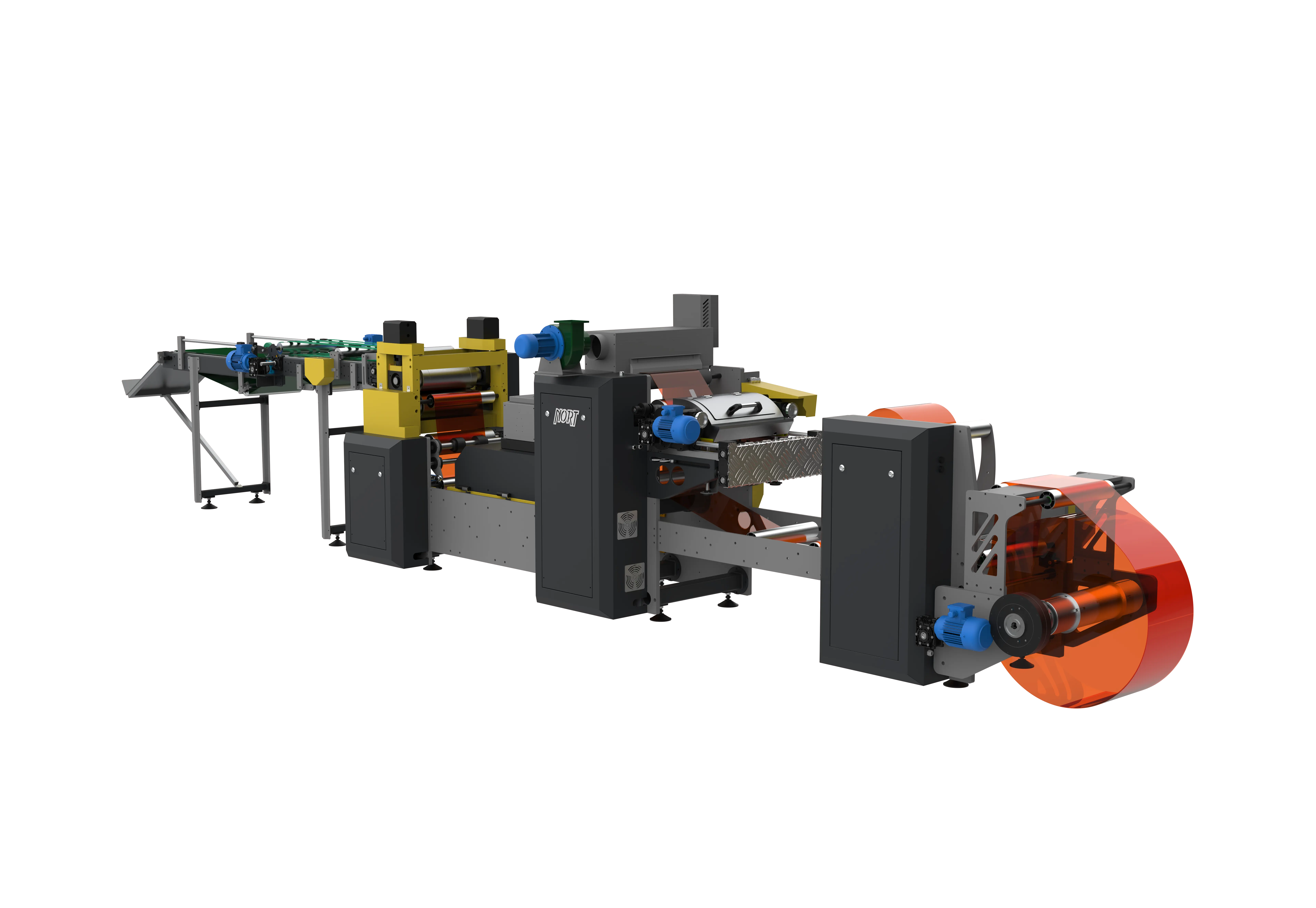

PRINTING FEATURES

· RUBBER SYSTEM : AVAILABLE

· PAINT ROLLER : TRAM ROLLER (COPPER PLATED)

· UNCOILER MAX : Ø 800mm

· WORKABLE PRODUCT WIDTH : 400 mm

· WORKABLE PRINTING WIDTH : 350 mm

· UNSOLVENTER BOBBIN DIAMETER : Ø 152 mm (6”) steel Airshaft

· PRINTING UNIT : 1 Color

· UNSOLVENTER TENSION : 152 mm (6”) ... 250 – 800 mm

· GEAR PITCH : 5 mm

· CLICHE THICKNESS : 1,14 mm

· MACHINE MECHANICAL SPEED : 60 m/min

· PRINTING SPEED : 60 m/min

· LENGTH REGISTER : SERVO MOTOR

· RIGHT LEFT REGISTER: MECHANICAL : ±10mm

· PRINTING DRYING : UV DRYING (SINGLE LAMP)

· CLICHE BOILER CYLINDER : PNEUMATIC CONTROL

· TRAM STAND BY SYSTEM : AC MOTOR (1 PIECE)

· ELECTRIC PAINT PUMP : NOT AVAILABLE

· ANILOX AND B. BOILER DRIVE SYS. : GEAR DRIVE

TEMPERING STATION

· 15 kW heating system (serpentine box resistance)

· Blowing fan : available

· Heat control : digital control

· Pneumatic opening system : available

· Max temperature : 100 ˚C

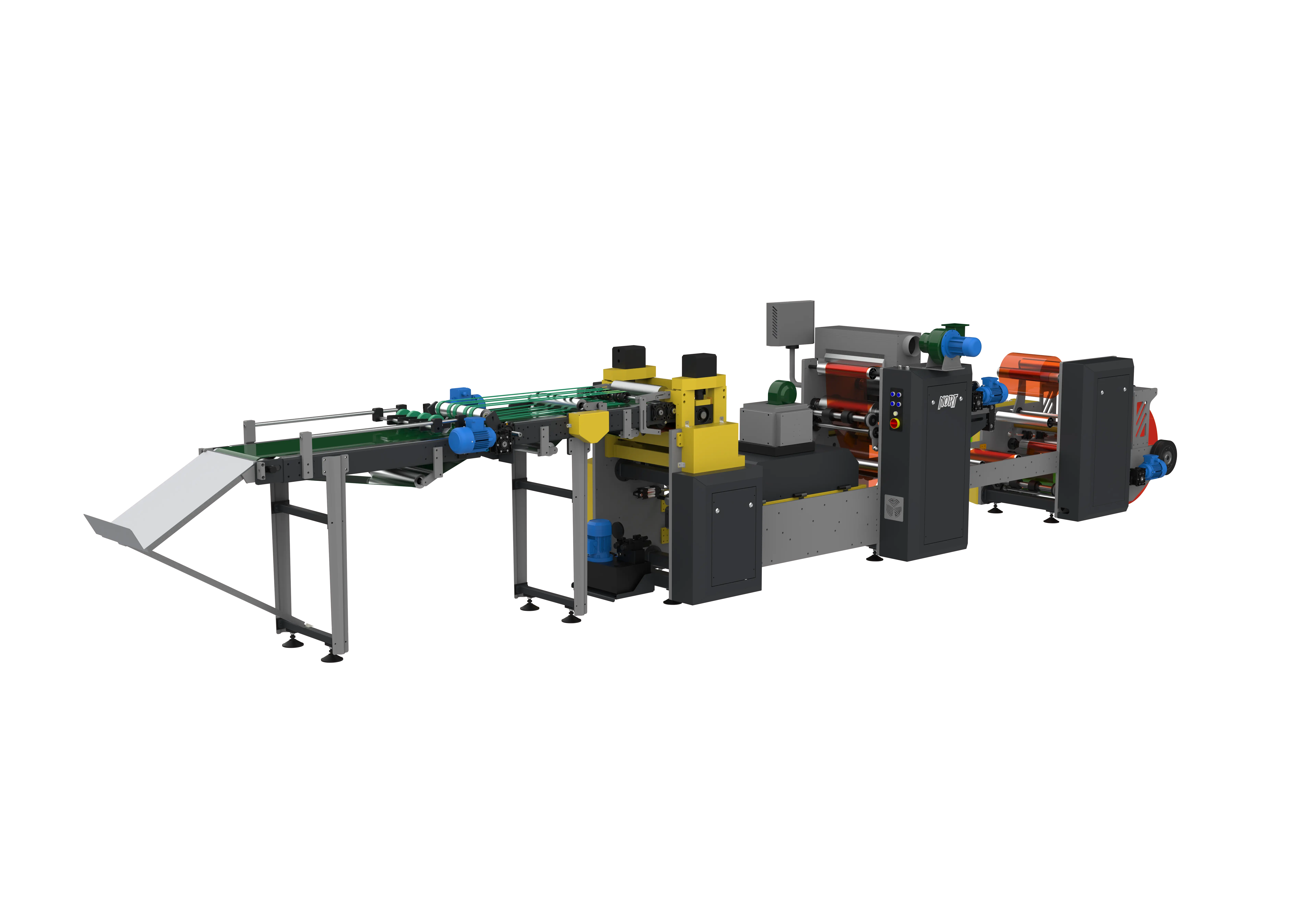

ROTARY BLADE

PRODUCT CUTTING SYSTEM : SINGLE BLADE ROTARY

MAX LENGTH CUTTING : 500 MM

LENGTH ADJUSTMENT : SERVO CONTROL

PRODUCT PULLING SYSTEM : SERVO MOTOR

PRESSING SYSTEM : HYDRAULIC CONTROL

The position of the cutting system according to the angle will be controlled by the color photocell. The servo system will make automatic adjustments if there is a slip.

GENERAL FEATURES

· AUTOMATION SYSTEM : KOLMORGEN PRODUCTS (USA)/ABB(GERMAN)

· ELECTRICAL PANEL : EXTERNAL PANEL

· SCREEN : 7 INCH

· SERVO QUANTITY : 4 PIECES

STACKING SYSTEM

Stacking system consists of conveyor drum conveyor system. The products cut by the blade will be sent to the drum via the conveyor and the drum will stack vertically and deliver them to the exit conveyor.